UWM/PROFI

Ultrasonic washing machine

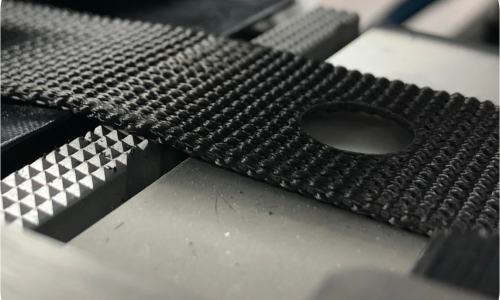

Ultrasound has a washing effect by its 20,000 vibrations per second directly into the textile materials and mechanically knocks the substances to be removed out of the fabric.

What is particularly sophisticated about ultrasonic washing is that the excess substances are not only removed from the material purely mechanically, but also by cavitation.

Ultrasound generates a periodic compression and expansion of the liquor absorbed by the material. Due to these pressure fluctuations, microscopic cavities form in the liquid.

The subsequent implosion of these cavitation bubbles filled with gas and water vapor leads to extreme local conditions, so that shear forces are created by the collapsing bubbles, which loosen the excess substances from the textile material at high speed.

Download UWM

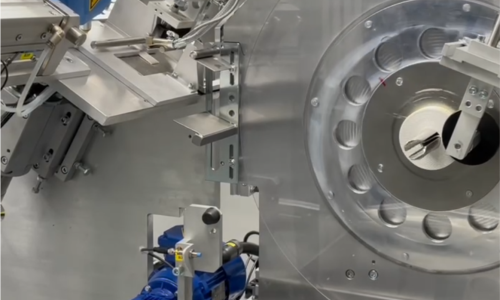

USM/80-3

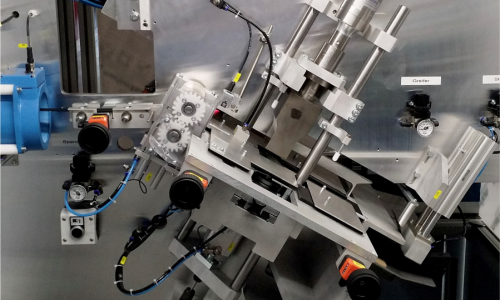

Ultrasonic cutting and punching machine

Ultrasonic cutting and punching machine with triple tool carrier. Each tool station can be equipped with customer-specific tools. All 3 tools can work individually, in parallel and/or subsequently and can be defined accordingly in a program recipe.

For extraordinarily precise dimensions, a motorized pre-driver is installed at the inlet to ensure low and constant stress conditions.

Customizable machine with many options such as larger sonotrode cutting surface (25 x 100), hot or cold cutting knife, marking device, patch defect detection (RGB), rapport detection, metal detection, stacker (1-4x) and much more.

Download USM/80-3

HSM/100-PROFI

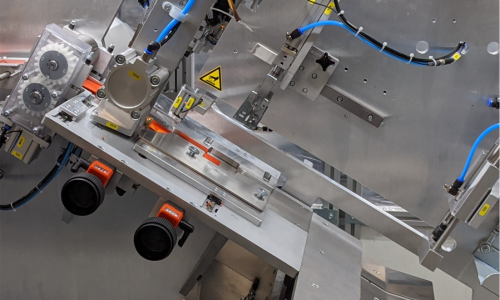

Hot cutting and punching machine

Hot cutting and punching machine with triple tool carrier and flattening device.

Each tool station can be equipped with customer-specific tools.

All 3 tools can work individually, in parallel and/or subsequently and can be defined accordingly in a program recipe.

For extraordinarily precise dimensions, a motorized pre-driver is installed at the inlet to ensure low and constant stress conditions.

Customizable machine with many options such as e.g. cold cutting knives, punching & slotting tools (hot), marking device, patch defect detection (RGB), rapport detection, metal detection, stacker (1-4x) and much more.

Download HSM/100-PROFI

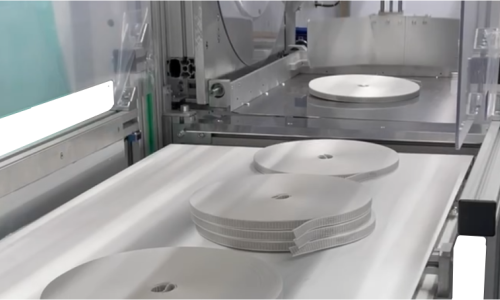

WAM/600

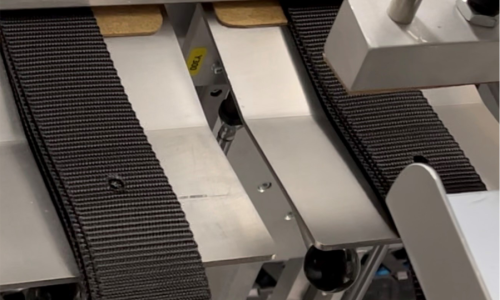

Winding machine for non-elastic synthetic textile tapes.

The winding unit operates at a speed of up to 250m/min and is freely programmable within a roll diameter of 600mm in terms of the length specification.

Due to the absolute synchronization of the winder motor and the feed motor, the tension is always the same but can also be adjusted if necessary.

For extraordinarily precise dimensions, a motorized pre-driver is installed at the input to ensure low and constant stress conditions.

Customizable machine with many options such as bigger roll winding diameter, metal clamp and/or hot melt fixation, hot and/or ultrasonic cut and punch modules, conveyor belt roll ejection with stacking function, marking device, patch defect detection (RGB), rapport detection, metal detection, stacker (1-4x) and much more.